|

|

|

|

|

Since 2004,

Nakayama Steel Works, Ltd., a medium-sized steel

manufacturing company, has been developing

technology for coating materials with amorphous

metals using the original coating device we

invented. Our latest technological development

introduced here consists of the following two

fundamental technologies.

|

(1) |

Development of chemical

components of amorphous metal with the highest

resistance to corrosion and

abrasion |

|

|

The Fe-35Cr amorphous metal we

developed this time has the world’s highest

resistance to corrosion. For example, the

Fe-35Cr amorphous metal corrodes by only 0.002

mm in aqua regia after one year, which is the

most corrosive reagent, at 25℃. |

| |

|

|

(2) |

World’s first small

metal-coating device |

|

|

We have developed a device for

coating parts (e.g., shafts) with amorphous

metals. This device can coat the surface of a

part with amorphous metals by melting the

Fe-35Cr amorphous metal described at 2600℃ and

then cooling it below 500℃ in 2 × 10-³ s or

faster (i.e., cooling rate is approximately

1,000,000℃/s). | | |

|

|

|

|

|

|

|

|

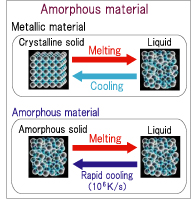

An amorphous solids is

obtained by melting an appropriate metallic

alloy and cooling at a rate of 1,000,000 oC/s or

higher.

When cooling

at a rate of 100 oC/s or lower, an ordinary

metal is obtained in which there is long-range

atomic order are called crystalline solids.

However, an amorphous metal has no crystal, in

which there is no long-range order of the

positions of the atoms.

|

|

| |

| Compared with

ordinary metals, amorphous metals exhibit

excellent performance, such as high resistances

to corrosion and abrasion, good soft magnetism

(easily magnetized),and good catalytic

performance (easily ionized). |

|

| | | |

|

|

|

|

|

High

corrosion resistance |

Corrosion

resistance of amorphous metals is more than ten

thousands times larger than that of stainless

steels. |

|

Hardness

with good ductility |

Compared to ordinal

metals, amorphous metals have about 3 to 10

times harder with good ductility. |

|

Easy

magnetism |

Being

random structure, amorphous metals have easy

magnetic

characteristics. | | |

|

|

|

|

|

|

|

|

Using a conventional

spraying gun, melting metal remains to be

crystalline solid due to insufficient cooling

rate. However, by newly developed spraying gun,

melting metals become amorphous after ultra

rapid cooling. |

|

|

|

|

|

|

|

|

|

Fe-Cr amorphous metals

have high corrosion resistance,

hardly-oxidization, abrasion resistance. This

amorphous materials are iron-based,

chromium-containing. They surpass stainless

steels. Furthermore, 35%-Cr amorphous metals

have more corrosion-resistant than Hastelloy C

that is known to be the highest corrosion

resistance. In Vickers hardness (HV) order, they

are three to four times harder than Hastelloy C.

|

|

|

|

|

(Weight loss after 1000

hours of dipping) |

|

- |

Fe-35Cr |

Fe-16Cr |

Fe-10Cr |

Ni-Mo |

HastelloyC |

|

35%HCL |

◎ |

× |

× |

◎ |

× |

|

98%H2SO4 |

◎ |

◎ |

◎ |

◎ |

◎ |

|

60%HNO3 |

◎ |

◎ |

◎ |

× |

◎ |

|

NaOCL |

◎ |

◎ |

◎ |

◎ |

× |

|

H3PO4+HF |

◎ |

× |

× |

− |

× |

|

Aqua

regia |

◎ |

◎ |

○ |

× |

× |

|

Hardness(Hv) |

1100 |

900 |

880 |

1000 |

330 |

|

Weight

loss |

◎Less than 1%

○1% or more but less than 5%

×5% or

more | |

| | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

| |

High

corrosion- and abrasion-resistance |

Shaft

sleeves of slurry pumps, impellers of slurry

pumps,Chemical tanks, sink rolls of acid

pickling baths

|

|

| |

Magnetic

characteristics |

Torque

sensors, motor cores, iron cores of power

transformers Magnetic shields |

|

|

Mechanical

characteristics |

Conveyor

rolls, separators of fuels cells, cutters

|

|

| |

|

|

|

|

|

|

|

Project

|

Development

of large amorphous or nano-structured metal film

using newly thermal spraying gun. |

|

Overview |

The project aims to

develop production process of high performance

amorphous or nano-structured metal films with

mass-production and low-cost.

The amorphous

films will be applied to fuel cells for electric

automobiles, which will reduce global

warming. |

|

Period |

August 1,

2010 to February 29,

2012 | | |

|

|

|

|

|

For inquiries about

contents

|

|

please |

|

FAX:+81-6-6555-4026

E-mail: | |

|

|

| |

|

- Amorphous

Development (Japanese)

- Application

of the actual parts (shaft sleeve of

pump)

- Application

of the actual parts (torque sensor)

- Amorphous

Development (English)

- Application

of the actual parts (shaft sleeve of

pump)

- Application

of the actual parts (torque

sensor)

|